Facing the global bulk material handling industry’s pressing need for higher efficiency, lower costs, and greater intelligence, traditional systems like wheel loader-dump truck methods and fixed stacker-reclaimer solutions have revealed their limitations. The Intelligent Stacker-Reclaimer (Compact Model) is a groundbreaking integrated equipment, merges crawler-track mobility, coordinated control of multi-degree-of-freedom mechanisms, and cloud-based intelligent management. This integration enables unified operations for material reclaiming, transfer, stacking, and quantitative truck loading. This paper aims to provide an in-depth analysis of its technical architecture, operational principles, core advantages, and the profound impact it generates within the industry.

I. Industry Pain Points and Drivers for Technological Innovation

In large bulk material yards, such as those found in ports, mines, and power plants, traditional operational models face inherent bottlenecks:

Wheel Loader-Dump Truck Systems: In the repetitive cycle of “loading – lifting – rotating – traveling – unloading,” non-productive time accounts for over two-thirds of the cycle, resulting in low effective productivity. Furthermore, dump truck capacity is limited, requiring frequent trips and leading to poor overall system efficiency.

Stacker-Reclaimer (Bucket Wheel Machine) Systems: While these systems offer high single-unit handling capacity, they suffer from a series of issues, including high initial investment, demanding civil engineering requirements, fixed location operation, and specialized and complex maintenance. This leads to a severe lack of flexibility.

The Intelligent Stacker-Reclaimer (Compact Model) was born precisely to address these challenges. It delivers 2.5 to 3 times the productivity of traditional wheel loaders at comparable power levels, while also incorporating the stacking capability of stacker-reclaimers. Furthermore, with an approximate 50% reduction in total investment and no need for complex foundations, it successfully unites high efficiency with remarkable cost-effectiveness.

II. System Architecture and Core Technology Analysis

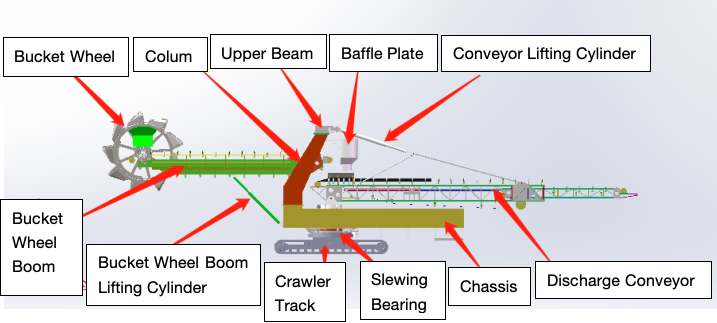

The Intelligent Stacker-Reclaimer (Compact Model) constitutes a sophisticated electro-hydraulic-mechanical integrated system. Its technological advancement is primarily manifested through the following core subsystems:

1. Mobile Chassis: Crawler Travel System

Utilizing a heavy-duty crawler chassis with low ground pressure ensures stable travel even in soft or uneven yard conditions.

Its core value lies in its full-site mobility, enabling the equipment to move flexibly between different work points, completely overcoming the spatial constraints of fixed installations.

2. High-Efficiency Reclaiming Unit: Screw/Bucket Wheel Reclaimer

Depending on material characteristics (such as coal, gravel, etc.), a screw reclaimer head or bucket wheel reclaimer head can be selected.

This unit is responsible for efficiently and continuously excavating material from the stockpile with minimal resistance and dust generation, forming the foundation for achieving a handling capacity of up to 1000 tons/hour.

3. Multi-Degree-of-Freedom Actuator: Enabling Full Area Coverage

Dual-Slewing Support System: This is a core upgrade in the second-generation machine. The dual design, featuring base slewing and boom slewing, significantly expands the working envelope for both reclaiming and discharging operations, eliminating dead zones.

Boom Luffing and Telescoping Mechanisms: The luffing mechanism adapts to stockpiles and trucks of varying heights, while the telescoping mechanism further extends the horizontal reach of the discharge point. The coordinated movement of these four key functions (travel, dual-slewing, luffing, telescoping) achieves seamless, comprehensive coverage of the work area.

4. Integrated Material Conveying System

The machine integrates an efficient internal belt conveyor. Material acquired by the reclaimer is rapidly and continuously transported via this “internal passageway” to the discharge chute at the boom end for truck loading or stockpiling.

5. Hybrid Power System: Dual Fuel/Electric Operation

With a total installed power of approximately 280 kW, it supports both diesel engine drive and external cable power supply.

This design provides exceptional environmental adaptability: it can operate in fuel mode in remote areas or new construction sites without external power, and switch to the more economical and eco-friendly pure electric mode when a fixed power source is available within a plant area.

III. Intelligent Control System: The Brain and Nerves of the Machine

The “intelligence” of the Intelligent Stacker-Reclaimer (Compact Model) is primarily embodied in its control system.

Local Intelligent Control: All operations can be performed via an advanced remote controller, allowing the operator to control the machine from a safe location with an optimal field of view. The control system employs precise closed-loop control over hydraulic flow, pressure, and speed, ensuring smooth operation and accurate movements.

Cloud-Based Intelligent Operation & Maintenance: This serves as the “wisdom brain” of the equipment. Through an intelligent cloud-based system, device data is uploaded to the cloud platform in real time. This enables technical personnel, even from thousands of miles away, to:

Monitor the real-time operational status of the entire machine (e.g., oil temperature, pressure, current, flow).

Perform fault early warning and diagnosis, identifying potential issues proactively and shifting from reactive repair to preventive maintenance.

Analyze operational data to provide data support for optimizing operational efficiency.

IV. Performance Parameters and Game-Changing Economic Analysis

1. Key Performance Parameters:

Handling Capacity: 1000 t/h (for coal, approx. 1100 m³/h), with a practical peak capacity reaching 1480 t/h.

Machine Weight: Approx. 80 tons.

Travel Speed: 5~10 m/min.

Noise Control: ≤80 dB, complying with stringent environmental standards.

Power System: Dual fuel/electric operation.

2. Disruptive Economic Comparison:

The core competitiveness of the Intelligent Stacker-Reclaimer (Compact Model) lies in its exceptionally low operational cost. The following is a direct comparison of cost per ton of material handled (using truck loading operations in China as an example):

Stacker-Reclaimer: ~CNY 20 /ton

Wheel Loader: ~CNY 2 /ton

Intelligent Stacker-Reclaimer (Compact Model) (Fuel-only mode): ~CNY 0.44 /ton

Intelligent Stacker-Reclaimer (Compact Model) (Electric-only mode): ~CNY 0.21 /ton

This data unequivocally demonstrates its superior economic performance over traditional solutions, offering enterprises substantial benefits in energy savings and operational efficiency gains.

V. Application Scenarios and Future Outlook

This equipment is widely applicable in storage yards across major industries such as bulk cargo ports, thermal power plants, metallurgy, coal, and building materials. It expertly handles tasks involving the excavation and stacking of bulk materials like coal, ore, and sand/gravel.

Looking ahead, with the further integration of visual recognition, autonomous driving, and big data technologies, the Intelligent Stacker-Reclaimer (Compact Model) is poised to achieve fully automated path planning, automatic obstacle avoidance, and precise autonomous truck loading, ultimately progressing towards the ultimate form of an unmanned, intelligent stockyard.

Conclusion

The Intelligent Stacker-Reclaimer (Compact Model) represents not merely a simple functional integration but a fundamental innovation in traditional bulk material handling processes. This is achieved through the deep technological fusion of a mobile chassis, multi-degree-of-freedom mechanisms, intelligent electronic control, and cloud connectivity. With its unparalleled operational efficiency, exceptional cost-effectiveness, and forward-looking intelligent capabilities, it is establishing itself as the core equipment and benchmark product driving the transformation of the bulk material handling industry towards greater efficiency, lower carbon emissions, and enhanced intelligence.