In the field of bulk material handling, especially in the field of train unloading, special unloading equipment is indispensable. These machines are designed to be efficient and simple to install, operate, and maintain while keeping costs low. What equipment is commonly used for unloading bulk materials on trains?

Mainly include wagon unloaders (chain bucket unloaders), wagon tipplers, excavators, grabs, and other equipment. These equipment are currently used in various industries to unload and train bulk materials.

What are the main bulk materials transported by train? First, we have to understand which bulk materials are mainly transported by train. The characteristics of these materials are that they are in the form of powder, granular, or block, the transportation volume is very large and the transportation distance is very long. Mainly include coal, coal powder, coke, limestone, iron oxide particles, ore, slag, cement clinker, etc. Now let’s focus on the features, pros, and cons of these devices.

Outline:

- What are the features, advantages, and disadvantages of a wagon tippler?

- What are the features, advantages, and disadvantages of a wagon unloader?

- What are the features, advantages, and disadvantages of excavators?

- What are the features, advantages, and disadvantages of grabs?

- Summary

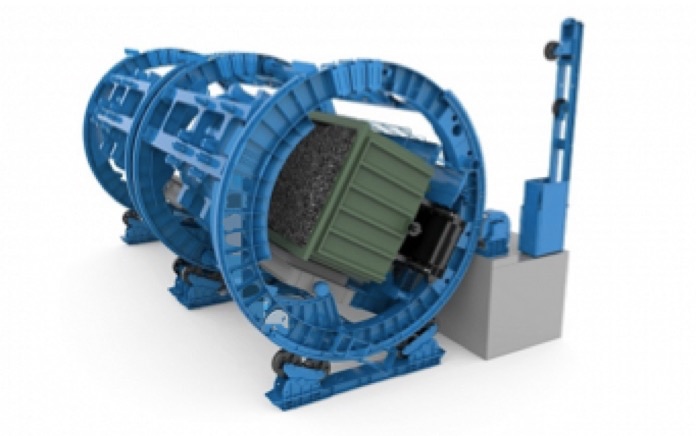

What are the features, advantages, and disadvantages of a wagon tippler?

Wagon tippler is currently a widely used equipment. It achieves the purpose of unloading by turning over the train wagons. It is also the most efficient equipment for unloading train bulk materials (coal, limestone, iron ore etc). One thing to note is that the wagon tippler is not suitable for all bulk materials. Some sticky bulk materials such as iron ore concentrate, copper concentrate, etc. will adhere to the carriage and cannot be unloaded well after dumping. They still need to Cooperate with manual or other equipment to unload materials. The wagon tippler is suitable for use in scenes where the unloading efficiency is very high. However, because the equipment is relatively expensive and additional foundations and basements need to be built under the train tracks, the overall cost not only needs to consider the equipment itself but also a large amount of civil construction costs, which puts greater financial pressure on the company. It also means that it needs to be planned in the early stages of train line construction and is not suitable for renovation on existing train lines.

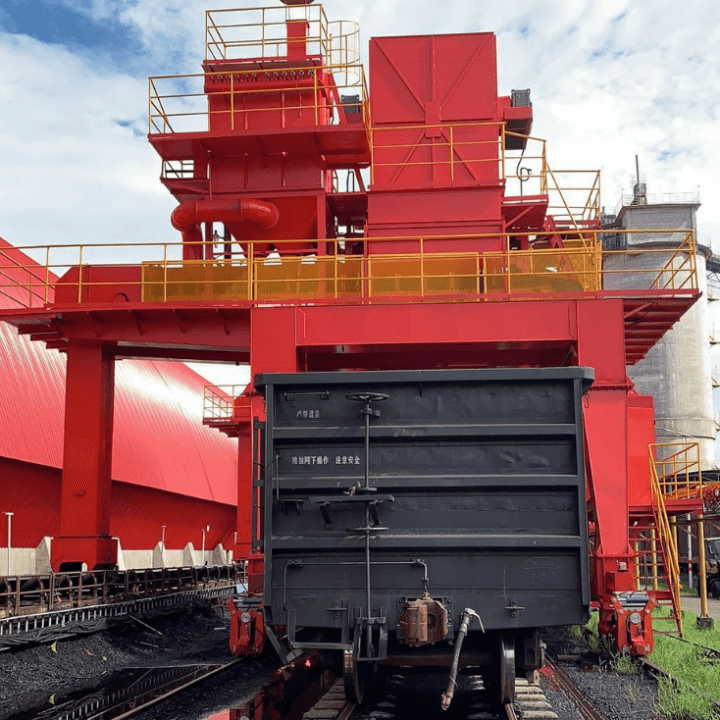

What are the features, advantages, and disadvantages of a wagon unloader?

It is a piece of equipment that spans the railway line. It uses a chain bucket to unload bulk materials in the wagon and transport them to the end of the equipment. It continuously and quickly transports the materials to the conveyor system through the funnel and transports the goods. to destination. Compared with the wagon tippler its efficiency is slightly slower because it cannot dump bulk materials out at one time. The overall efficiency is about one-third of the dumper. However, because its overall cost is much lower than that of a wagon tippler and its efficiency is high, if the site permits, some companies will use multiple unloaders to double the efficiency. The overall effect is even better than that of a wagon tippler because it needn’t build a foundation. For additional modifications in civil engineering, equipment tracks only need to be laid on the outside of the train track. This makes the train unloader a good choice if some railway lines that have been used for many years need to upgrade their unloading efficiency. Some companies will use multiple unloading machines to double their efficiency, instead of choosing wagon tipplers to reduce one-time capital investment. It is worth mentioning that even if you purchase multiple unloading machines at one time, its capital investment is still less than the overall cost of a wagon tippler.

What are the features, advantages, and disadvantages of excavators?

The excavator is usually mounted on a platform above the carriage and unloads materials through a bucket. The efficiency is relatively slow. However, due to its low cost, many companies still choose it for unloading. It should be noted that although the cost of the equipment itself is low, daily operation, maintenance, and use costs also need to be considered, such as annual fuel costs, costs incurred by waiting for the unloading of trains, and the costs of professional drivers, etc. Not only that, it is easy to damage the vehicle’s skin during operation.

What are the features, advantages, and disadvantages of grabs?

The working principle of Grab and similar excavators is relatively slow, but the cost is low, and it is also a good choice for companies that do not have particularly high efficiency requirements.

Conclusion

The above is a comparison of commonly used equipment for unloading bulk materials in trains. Of course, some companies will use bottom dump trucks to unload bulk materials from the bottom of the train carriage. This method will not be discussed. Different equipment is suitable for different usage scenarios, which is a necessity in modern industry. It significantly increases efficiency while reducing manual labor and operating costs.

One Response

Thank you very much for your article, it helped me a lot