At present, train bulk material unloading mainly uses equipment such as wagon tipplers, wagon unloaders, and excavators. However, no matter what equipment is used, the bulk materials in the wagon cannot be unloaded cleanly. There will still be some residual material, and finally, it still needs to be cleaned manually again. To solve this problem, the NEWTECH company from China has launched a brand new equipment, the wagon cleaning machine. This eliminates the need for manual cleaning of the final remaining materials, achieving full automation in the true sense of train bulk material unloading.

What is the wagon cleaner?

The train wagon cleaner is a device used to automatically collect the remaining materials in the wagon during the unloading process of train bulk materials. It can clean the residual materials in the train wagon without opening the wagon door. Improve the cleaning efficiency, and realize closed operation in the whole process, which is safe and environmentally friendly.

Outline

- Advantages and features of train wagon cleaner

- Working principle of train wagon cleaner

- What parts does a train wagon cleaner consist of?

- What are the main parameters of the train wagon cleaner?

- What working conditions are the train wagon cleaners suitable for?

- Overview

Advantages and features of train wagon cleaner

- Safety: There is no need to open the wagon door, and no one is involved in the entire cleaning process;

- High efficiency: It takes 2 to 3 minutes to clean one wagon, and multiple equipment can be operated in conjunction;

- Efficiency increase: One piece of equipment can replace 8 to 10 workers, helping enterprises to mechanize instead of labor, thereby reducing staff and increasing efficiency;

- Intelligence: One-click start and stop, automatic addressing and positioning, and automatic completion of cleaning operations;

- Environmental protection: The equipment adopts the principle of negative pressure transportation, and the cleaning process will not produce dust.

Working principle of train wagon cleaner.

During the wagon cleaning operation, press the automatic button, and the laser control system controls the equipment to automatically find the position of the wagon. When it reaches the appropriate position, the electrical control system starts the negative pressure conveying system and the hydraulic system in sequence. The lifting system drives the cleaning system down. After touching the bottom of the wagon, the control system controls the movement of the mobile platform, which in turn drives the lifting system and cleaning system to move along the length of the wagon. During the movement of the mobile platform, the combination of the disc brush and the spiral in the cleaning system collects the debris in the wagon to the negative pressure suction port and realizes the collection and fixed-point release of debris through the negative pressure conveying system.

What parts does a train wagon cleaner consist of?

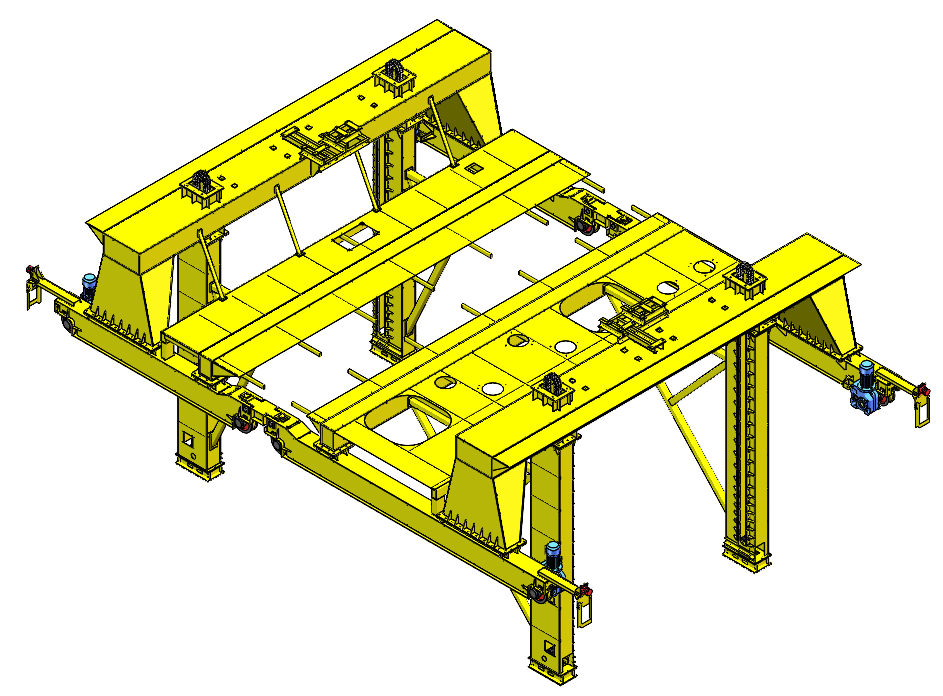

1. Main system

The main system mainly consists of a lifting mechanism, a trolley traveling mechanism, an end beam mechanism, a driver’s cab, etc. The main load-bearing components such as the main beam are manufactured in accordance with the GB/T14406 (General Gantry Crane) standard. The inspection of welding processes and welds strictly abides by corresponding specifications and standards, and X-ray films and ultrasonic non-destructive testing are performed on important welds. The wheel material is 65Mn, and the gear material is 20CrMnTi, ZG35SiMn, 42CrMo, etc. In terms of traveling and lifting, multiple travel switches, limit switches, anti-fall measures, and buffer switches are also installed to ensure the safety of equipment operation.

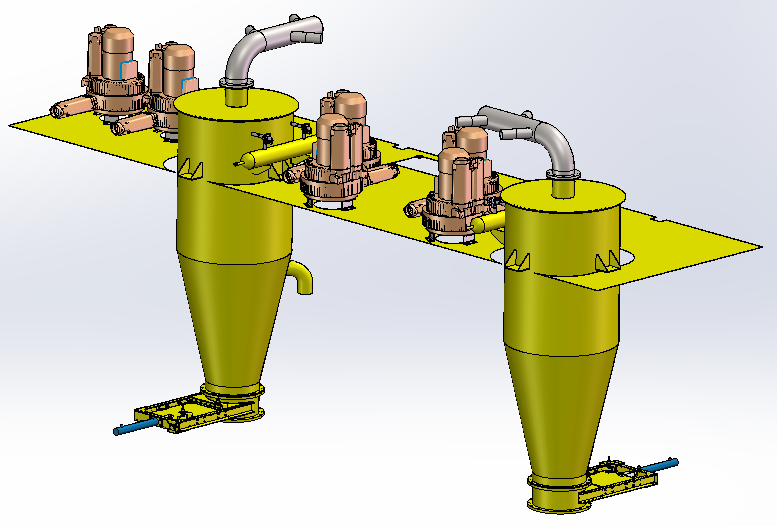

2. Negative pressure system

The wagon cleaner machine is equipped with a centrifugal fan with high negative pressure and high air volume as the driving source of the negative pressure system. It uses the super suction generated by the turbine to peel off and collect materials adhered to the car. The negative pressure conveying system can realize simultaneous absorption of dry and wet materials. The maximum diameter of the suction material is 180mm.

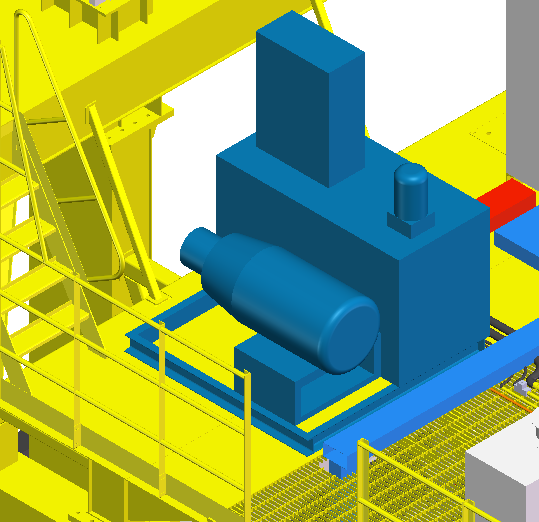

3. Hydraulic system

The hydraulic system is equipped with safety devices to prevent overload and shock. When using a relief valve, the maximum working pressure of the relief valve shall not exceed 1.1 times the maximum working pressure of the system, and shall not be greater than the rated pressure of the hydraulic pump. The system working pressure is 16MPa.

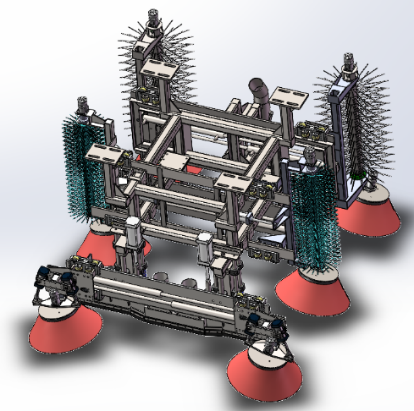

4. Cleaning system

The cleaning system mainly cleans the bottom, surroundings, and upper frame of the wagon to collect materials in the wagon. The cleaning device is equipped with 4 sets of side roller brushes, 4 sets of bottom disk brushes, and 2 sets of top cleaning brushes, a total of 10 sets of cleaning brushes, and 10 Sets of cleaning brushes can work simultaneously. Among them, 4 sets of side roller brushes are used to clean the residual materials on both sides of the train wagon and the reinforcement ribs. 4 sets of bottom disc brushes are arranged under the side roller brushes to clean the accumulation physics in the corners of the bottom of the wagon. 2 sets of cleaning brushes are used for cleaning the top of the wagon. Clean the remaining material on the top of the wagon body. The side brush has horizontal expansion and contraction functions. The roller brush on the side of the cleaning device is equipped with an elastic device, which can adapt to the cleaning of the wagon wall when the deformation of the old wagon causes the wagon to open. The equipment cleaning device is equipped with ultrasonic detection; all driving mechanisms use hydraulic motors.

5. Monitoring system

The wagon cleaner is equipped with four surveillance cameras to monitor the conditions inside the wagon and the front and rear position images of the wagon being cleaned during the cleaning process. The maximum resolution of the video surveillance system can reach 1920*1080@25fps, and real-time images can be output at this resolution. Supports backlight compensation, strong light suppression, and 3D digital noise reduction. The monitor of the monitoring system is placed on the equipment operating table to remotely monitor the operation of the equipment. The surveillance system needs to have a storage function that can play the stored videos within 7 days at any time.

What are the main parameters of the train wagon cleaner?

| No | Name | Parameters |

| 1 | Materials | For iron powder, pellets, coal, burnt ore, and other bulk materials, the particle size of the material to be cleaned is ≤180mm. |

| 2 | Types of wagons | Applicable to common gondola models. |

| 3 | Cleaning of range | Can clean the remaining materials at the bottom of the wagon, the four walls of the wagon and the top of the frame. |

| 4 | Cleaning efficiency | The cleaning time of a single wagon is about 3 minutes (the actual cleaning efficiency is related to the amount of residue in the wagon). |

| 5 | Cleaning quality | The total weight of the remaining materials after cleaning should not exceed 10kg/wagon. |

| 6 | Clean quantity | Meet the cleaning needs of 200 wagons and more every day. |

| 7 | Continuous running time | Can meet continuous 24-hour operation requirements. |

| 8 | Operational safety performance | The equipment has automatic protection and warning functions. The wagon unloader and cleaning equipment have established a safety interlocking mechanism and do not constitute cross-operation. |

What working conditions are the train wagon cleaners suitable for?

In principle, train wagon cleaner can be used as long as there are trains unloading bulk materials (metallurgy, thermal power generation, cement plants, coking, coal preparation, coal chemical industry, ports, coal logistics and bulk cargo storage bases, etc.). It is mainly used with automated equipment such as wagon tipplers, wagon unloaders, and excavators.

Overview

As an expert in providing bulk material handling system solutions, NEWTECH is well aware of the pain points and difficulties faced by enterprises in their work. In the future, through our continuous optimization and improvement of equipment, the cleaning machine will be applicable in more working conditions and bring benefits and efficiency improvements to more companies.

2 Responses

Very helpful

Needs details